Our Approach

Iron as Energy Carrier

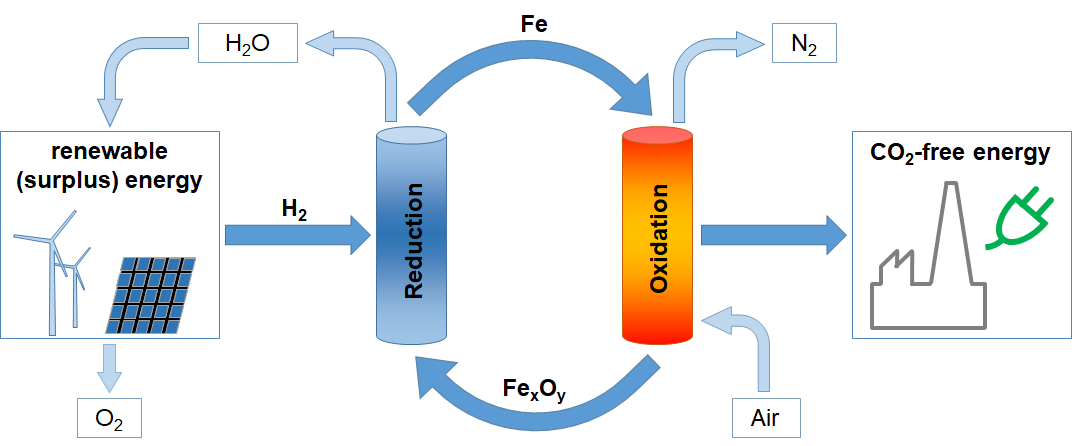

This project introduces an innovative approach to energy storage and CO₂–free heat and power generation by harnessing the cyclic reduction and oxidation of metal oxides. The process employs a retrofittable approach to existing coal-fired fluidized bed power plants, utilizing a hydrogen-based reduction of metal oxides and subsequent oxidation in fluidized beds. This cycle not only leverages existing infrastructure but also eliminates CO₂ emissions. With iron as a cost-effective, energy-dense material, this system can store energy seasonally and offer scalable solutions for energy storage. Key technical developments focus on optimizing boiler efficiency, integrating particle feeding/extraction, and enhancing overall economic and environmental viability.

The process

How the power generation process works

Excess electricity can be used to produce green hydrogen, which can be used to reduce iron oxide to iron in an endothermic process.

The reduced iron can be stored and transported to where it is needed.

If required, the reduced iron can be oxidised in a CO2-free process to produce iron oxide for energy generation. The cycle starts again.

Related Projects

Clean Circles

The Clean Circles project explores how metal and its oxides can be used in a closed cycle as a carbon-free chemical energy carrier to store wind and solar energy.

It involves scientists from Technische Universität Darmstadt, Hochschule Darmstadt, Universität Mainz, Karlsruhe Institute of Technology, Universität Heidelberg, the Max Planck Institute for Sustainable Materials, and the DLR Institute for Low-Carbon Industrial Processes.